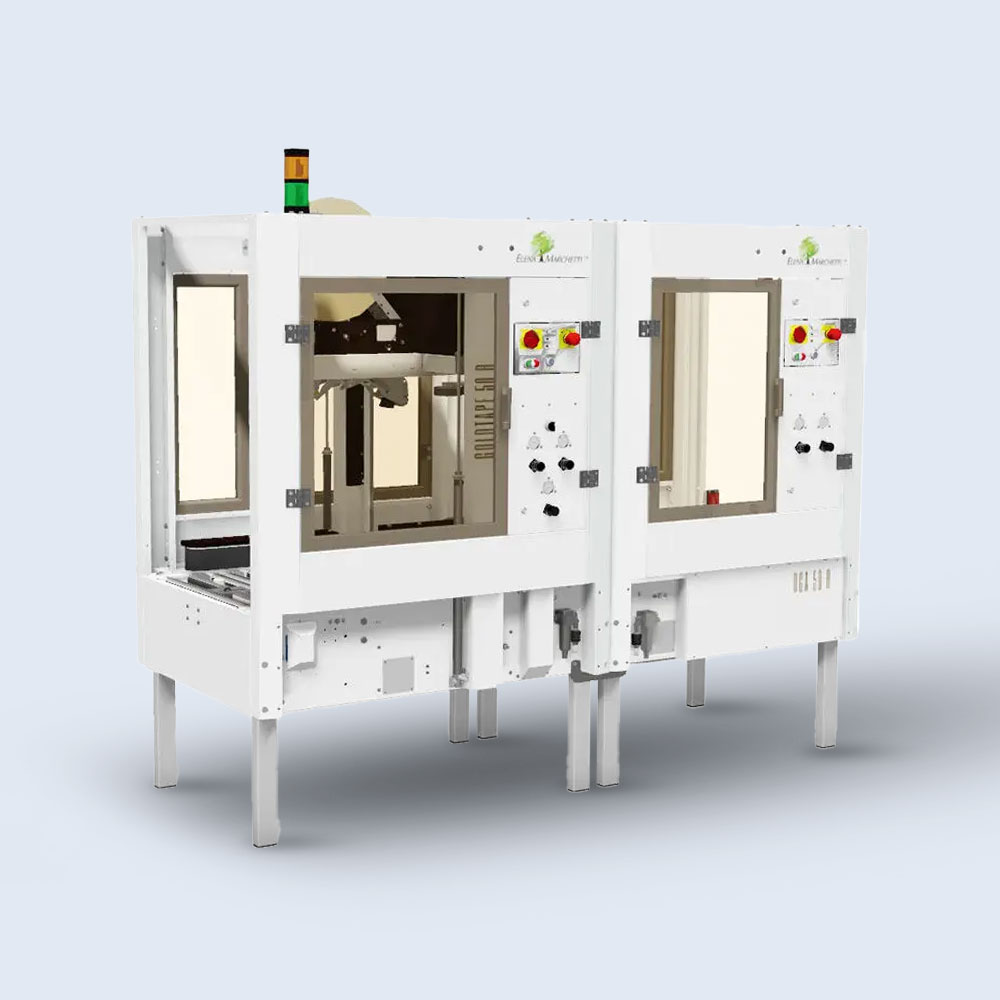

Goldtape 65RL

In the semi-automatic work cycle, the operator squares the box and places it on an infeed roller conveyor with the lower flaps folded. When the box is filled, the operator folds the upper flaps and starts it on a motorized cadence / centering device (DCA R) and then get into the sealer.

In the automatic work cycle, the box comes from an automatic line with the lower flaps folded and the upper flaps folded (45 °). Once it arrives at the machine entrance, the box activate the switches that will adjust the driving belt and top taping head frame on the box sizes.

While the boxes pass through the machine, the top and bottom flaps will be sealed simultaneously from the taping heads. At the end of the cycle, the machine positions itself to accept the next box.

Key Features

- Machine table made of free metal rollers

- Two columns frame with one piston each to symmetrically move top taping head

- Safety transparent protections with unique coding RFID to cut electricity and pneumatics when the doors are open (CE certified)

- Top frame excursion limitation with a limit switch to increase the machine working cycle

- Control panel with working cycle management (box in-feed – taping – out-feed – indexing connection management) in automatic function

- 2 taping heads TU2 (top & bottom), tape 50mm width ( GT50RL) – TU3 ( GT65RL,GT80RL),from 25 to 75mm width heads on request